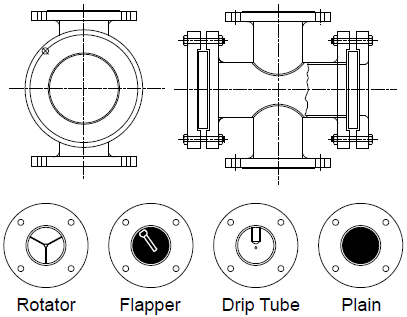

Flowtel sight flow indicators provides a quick, reliable and economical way to verify fluid flows through industrial process lines. Sight Flow Indicator is available with four styles of indicators including rotar wheel, flapper, or drip tube, Plain. A rotar wheel indicator style is ideal for indicating flow of clear or opaque liquids as well as observations from a distance. It can be installed in any direction, upward, downward, vertical or horizontal lines. A flap indicates at a glance which direction the flow is moving in horizontal lines or vertical lines with upward flow. A port in the shape of a whistle or drip tube is ideal for gravity flow, extremely low flow or intermittent flow. The drip tube keeps the fluid from dripping on the sight glass, ensuring visibility.

DOUBLE WINDOW SIGHT FLOW INDICATOR

| NB |

Face to Face IN MM |

Visible Dia IN MM |

| 15 |

160 |

38 |

| 20 |

160 |

38 |

| 25 |

160 |

38 |

| 40 |

200 |

50 |

| 50 |

230 |

65 |

| 65 |

310 |

96 |

| 80 |

310 |

96 |

| 100 |

350 |

150 |

FEATURES & BENEFITS

- Simple, reliable and economical way to verify liquid

flows through industrial process lines

- Many specials are available upon request to meet

various conditions of pressure, temperature,

fluid types and mechanical dimensions

DOUBLE WINDOW SIGHT FLOW INDICATOR

| Item |

: Sight glass |

| Type |

: Double window |

| Nuts & bolts |

: Carbon steel/SS-304/SS-316 |

| Sealing |

: CAF/PTFE/METALLIC GRAPHITE/SPIRAL WOUND |

| Cushion |

: CAF/PTFE/METALLIC GRAPHITE/SPIRAL WOUND |

| Cover Plate |

: M.S/ SS-304/SS-316 |

| Body Material |

: ASTMA A216 Gr. WCB/ASTM 351 CF8/ ASTM351CF8M/A106 GRB/Carbon steel/SS-304/SS-316 |

| End Connection |

: Flanged/ screwed |

SPECIFICATION

| Item |

: Sight glass |

| Type |

: Full view |

| Glass |

: Borosilicate with flare end |

| Packing |

:PTFE |

| F/F Distance |

: 150 mm |

| End Connection |

: Screwed/ flanged etc. |

| Tie Rod & Flanges |

: SS-316L, SS-316, SS-304L, SS-304,MS,PTFE BUSH & WASHER |

FULL VIEW SIGHT FLOW INDICATOR

| SIZE(NB) |

F/F DistanceIN MM |

| 15 |

150 |

| 20 |

150 |

| 25 |

150 |

| 40 |

150 |

| 50 |

150 |

| 80 |

150 |

| 100 |

150 |

DETAILS REQUIRED FOR QUOTATION

| (1) Type (full view or double window) |

(4) Operating pressure |

| (2) Size |

(5) Operating temperature |

| (3) End connection detail |

(6) Material of construction |