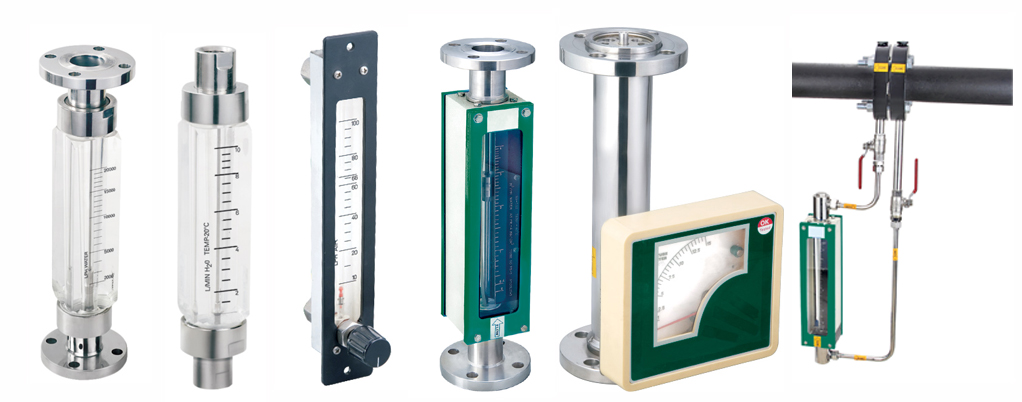

ROTAMETER

What are Rotameters ?

The rotameter is an industrial flowmeter used to measure the flowrate of liquids

and gases. The rotameter consists of a tube and float. The float response to

flowrate changes is linear, and a 10-to-1 flow range or turndown is standard. In the case of Flowtel Engineering, far greater flexibility is possible through the use of correlation equations. The rotameter is popular because it has a linear scale, a

relatively long measurement range, and low pressure drop. It is simple to install

and maintain.

Application

These meters with all steel and plastic fittings to eliminate corrosion

completely. The meters are useful for measuring flow of air, common

gases, water and many organic chemicals, excluding petroleum

products. Applications include purging of gas lines, anaesthesia,

laboratory instruments, leak detection, cable pressurization, industrial

furnaces and chromatography etc.

Rotameter Selection

The key questions which need to be answered before selecting a rotameter are:

. What is the fluids?

· What is the minimum and maximum flow rate for the flow meter?

· What is the minimum and maximum process temperature?

· What is the size of the pipe?

· Would you like a direct reading rotameter or is a lookup table acceptable?

· What accuracy do you need?

· Do you require a valve to regulate the flow?

· Will there be back pressure?

· What is the maximum process pressure?

Principle of Operation

The rotameter’s operation is based on the variable area principle: fluid flow raises a float in a tapered tube, increasing the area for passage of the fluid. The greater the flow, the higher the float is raised. The height of the float is directly proportional to the flowrate. With liquids, the float is raised by a combination of the buoyancy of the liquid and the velocity head of the fluid.

With gases, buoyancy is negligible, and the float responds to the velocity head alone. The float moves up or down in the tube in

proportion to the fluid flowrate and the annular area between the float and the tube wall. The float reaches a stable position in the tube when the upward force exerted by the flowing fluid equals the downward gravitational force exerted by the weight of the float. A change in flowrate upsets this balance of forces. The float then moves up or down, changing the annular area until it again reaches a position where the forces are in equilibrium. To satisfy the force equation, the rotameter float assumes a distinct position for every constant flowrate. However, it is important

to note that because the float position is gravity dependent, rotameters must be vertically oriented and mounted.